Facilities

Lehi Sheet Metal is committed to giving our customers the best quality, service, and on-time delivery. To achieve this goal we utilize today's latest technology in manufacturing.

Laser Cutting

(1) 2021 Mitsubishi 3015 GX-F Advanced 8.0kw Fiber Laser System

diamond CAM with NCell Load/Unload. The 5’x10’ table cuts 1” steel, 5/8”stainless steel and 1/2” aluminum.

(1) 2005 Mitsubishi 3500w Co2 laser with NCell Pallet load / unload.

(1) 2006 Mitsubishi 4000W Co2 laser. 5’ x 10’ table, cuts 1” steel, 5/8” stainless steel and 1/2” aluminum

Job Tracking

Visual Manufacturing System from Infor - Visual 10.0

Integrating all aspects of the production process, from estimating to scheduling to billing. Includes detailed finite scheduling, real time barcode labor tracking, and inventory management.

Windows 2010 server

With Windows 2010 clients. Integrating job tracking, e-mail, faxing, and wi-fi enabled office.

Engineering

AutoCAD

Pro/ENGINEER

SOLIDWORKS

Cad/Key

Metalsoft turret programming software

Punching

Finn Power TP-2525-IF5, CNC 87 station turret punch press with 3 autoindex stations and brush table. Capable of punching a 10' x 4' sheet.

Forming

2023 Cone-G40 Press Brake. CNC Controlled Y1,Y2,Y3,Y4,Y5,Y6, X, R-Axis with 2 PCS Back Gauge Fingers. Automatic crowning.

Toyokoki HYP1253 125 ton press brake with 10' bed, autocrowning, material sensing and auto back gage

Toyokoki HYP1753 175 ton press brake with 10’ bed, autocrowning, material sensing and auto back gauge.

Chicago 150 ton press brake with 10' bed and DRC auto back gauge

Chicago 90 ton press brake with 6' bed and AutoMec back gauge

Welding

5' x 7' Weldsale platten for improved quality assemblies and weldments

(2) Miller Syncrowave 350 LX Tig welders

(2) Miller Millerwave 250 Mig welders

(2) Lincoln Idealarc 300 Tig welders

(2) Lincoln Wirematic 200 Mig welders

(3) Spotwelders with capacity up to 150 KVA

2021 IPG Light Weld 1500-5M Laser Welding System

5' x 7' weld platten

Airflow exhaust system

ABB Robotic Welder

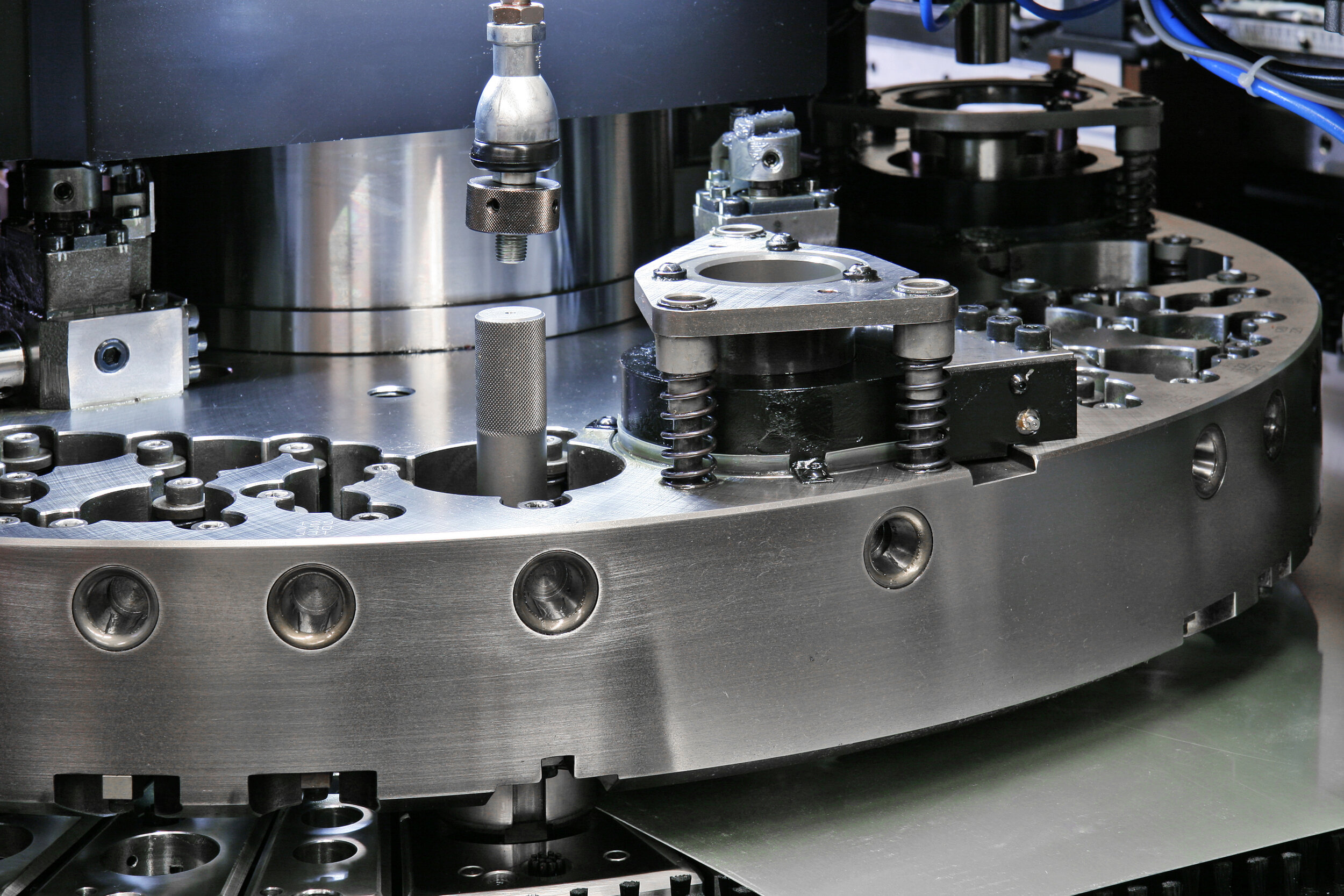

Robotics

ABB FlexArc C System - 6 axis robot welder with Orbit IRBP 500 2 station position and Binzel Robo 455 water cooled welding torch.

Hardware

(1) Haeger 824 WindowTouch 8-ton insert machine with auto-feed, touchscreen and InsertionLogic software

(2) Haeger HP6 6-ton insert machines

Inspection

Hexagon Absolute 8525 7-Axis Inspection Arm

6" and 12" Mitutoyo dial calipers

24" and 40" Mitutoyo verniers

Mitutoyo micrometers

Starret gauge blocks

Complete set of pin gauges from .011 to .500

Tapped hole go-no go gages, standard and metric

All equipment calibrated by Hunt Metrology

Machining

Access to onsite state-of-the-art CNC machining centers as well as CNC lathes.

(2) Rolling machines

(2) Cold cut-off saws

(1) Horizontal band saw

(1) Vertical band saw

Painting and Silkscreening

Painting and Silkscreening

(2) 10' x 12' spray booths

(1) 10’ x 12’ GFS powder coating recovery booth

(1) 9' x 10' Binks powder coating booth

(2) Binks 2001 spray guns

(2) Devilbiss spray guns

(4) Binks 2 gallon pressure pots

Nordson "Sure coat" powder coating system

Full service silkscreening department

Other

GrindMaster 2000 37" x 75" autogauge sander

(2) Timesaver sander / costa levigatrici 40” wide

(3) Tumblers

Wysong 8' shear

(4) Single station punch presses

(2) Forklifts

12’ BGB stroke sanding machine